Alex Lim-Fat’s Story & 3D Printing for Accelerator Technology Improvements (submitted)

I was born in 1987 in Toronto, Ontario. My parents, Donald Lim-Fat and Sonia Lee, were both Mauritian immigrants who met in Toronto and got married there in the early 80s. They had spent their young adult lives studying and living in Toronto, and made good lives for themselves. My father was a software engineer turned manager at IBM and mom, a nurse. Despite loving Toronto and Canada, they missed Mauritius and made the tough decision to move back in 1990.

Mauritius is a small tropical island, roughly 1000 kms to the east of Madagascar. Needless to say, very different from Canada. Being 4 years old, I was initially at times annoyed at the lack of creature comforts available in Canada (Our cool Volvo 240 Station Wagon, Toys-R-Us stores) but quickly got used to the island life and embraced it for the next 15 years.

Looking back, my parents had a very positive influence on me and my brothers. My mother was strict. Other than allowing me and my brothers to watch the odd movie or TV show, we mostly watched local and international news, no gaming consoles were bought, and we mostly read educational books. My favourite books were the Dorling Kindersley ones, which covered almost any imaginable topic in science and technology. Our house in a town called Quatre Bornes was like a mini zoo. We had all sorts of fish, turtles, dogs, rabbits and pet birds. A lot of our weekends were spent going on fishing trips and relaxing on beaches. For sports, my parents enrolled me and my brothers in tennis and swimming classes. I was an avid cyclist in my early teens but discovered skateboarding in 2001 and was so mesmerized by it that I dropped everything else and still do it to this day. I went to a Catholic High School that required us to wear a proper uniform and excel in both athletics and studies.

In Mauritius, almost everyone speaks at least 3 languages. We speak Mauritian Creole when in an informal setting (which is what I use when talking to my relatives), French when in a formal setting (e.g, when talking to a boss at work) and most formal documents, from school textbooks, to official documents are in English. In addition to that some of my friends would speak other native languages at home with their relatives.

In 2001, I was in Form 3 and 14 years old. During that era (and this might possibly still be the case), students were required to choose whether they wanted to specialize in the sciences or Economics/Accounting. I chose the latter combo because I found it easier. That was a decision that I would later regret, because even though Economics/Accounting are indeed in general easier than Science, and I did get good grades in Economics, I did not find the latter interesting, so in a way, it was harder.

I enrolled at Simon Fraser University in 2006, with the intention of majoring in economics because that’s what I majored in in high school. After a couple years of lackluster performance and still not interested the topic, I abandoned the program and did odd jobs for the next few years, working at the Burnaby Public Library as a Page (Book re-shelver) and tutoring math and French to high school and entry level university students.

In late 2012, I was 25 and getting concerned that I wasn’t on track at establishing a career for myself at an age when a lot of my friends were already in the workforce with proper 9-5 jobs and salaries. After pondering for a while on what to do, it dawned on me that I should give a shot at something I was passionate about. My mind raced back to when I was a child, enjoying reading about cars and airplanes and I was decent at math, so I decided to study mechanical engineering. My father was skeptical at my choice, because mechanical engineering is more difficult than economics, but he believed in me and funded my studies, which I am forever extremely grateful for.

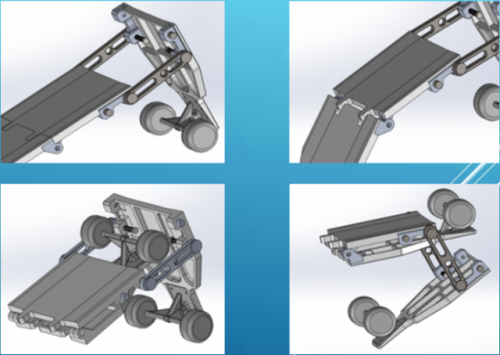

BCIT in Burnaby, BC, Canada had a mechanical engineering program that was getting accredited and is a school that accepts older students who are from all walks of life, so it was the best choice for me. Coincidentally, I had also fulfilled the prerequisites, which were Physics and Chemistry courses that I previously took as electives (odd choice for an Arts student, but I found them interesting). I found the program very difficult but nonetheless very enjoyable because it does a good job at blending theory with hands on experience. I loved the machining and welding classes. The thing that I’m most proud of, other than surviving the program, is my final year project. With the help of a great team, we designed and manufactured a fold-able skateboard from scratch that would fit in a backpack. It was an ambitious undertaking, especially for second year students, due to the tight time-frame and complexity of the mechanism, but we pulled it off. The pictures below show the design, locking mechanism, Finite Element Analysis screenshot and actual final product that we finished in time for the expo.

The program offers a 4 year degree. After the 1st 2 years, the students are awarded a diploma and gain the title of technologist. They can use that qualification to find work in the industry and choose to come back to complete their studies.

At that time, I felt that I needed a break from studies so I began applying for work after I got my diploma.

After sending out many applications and getting no replies, I one day received an email from Dave Lewis, my program head at the time. A company called D-Pace was looking for a mechanical designer and the job description sounded amazing to me. I did a Google search on the company and saw how it was tied to TRIUMF, which I had visited during a field trip and was absolutely blown away by, from the particle cloud chamber near the entrance to the giant particle beamlines and miscellaneous experiments being done.

I immediately phoned the company and spoke to Thomas Stewart, who was doing the hiring to enquire whether he would consider my application, because I had specialized in the manufacturing side of the program (as opposed to the design side). Fortunately, he confirmed that he would and encouraged me to do send in an application.

I was shortlisted for an interview and it was carried out in a classroom at BCIT. A few days later, I got a phone call, announcing that I got the job and was absolutely thrilled.

I was intimidated at the thought of having to relocate to Nelson, BC but some of my close friends who are from Christina Lake and Grand Forks, assured me that it is an amazing place and they were not wrong.

Nelson BC is not an easily accessible place. The drive from Vancouver, BC to Nelson was a beautiful but grueling one. That’s however most likely what has kept it so pristine and insulated from anything that would affect its charm.

Back in 2015, D-Pace had a small team and it was a great opportunity for me to learn, because my tasks were varied. The project that I worked on that stood out the most was the UniBEaM, a particle beam profiling system. I worked on the design of the controller box on Autodesk Inventor, sourced the raw materials and assembled the first few serial numbers.

The workplace atmosphere was very pleasant and I got along very well with everyone. I worked with excellent engineers and mechanical designers and learnt a lot from them.

After about 2 years, the company went through a difficult patch and I was laid off. Despite that, we parted ways on good terms and I got excellent references from my employers.

While we were going through those difficult times, I had pondered where to apply next if I had to.

One of the options was Buckley Systems Ltd (BSL), a company based in Auckland, New Zealand. BSL is the company that manufactures most of D-Pace’s products, among many others. Its products are very well made and it has established itself as one of the top electromagnet manufacturers in the world, so it would be a great place to work at. I also felt that it was a good opportunity to move to somewhere closer to family, because my brothers have made Australia their home for over a decade.

The founder of D-Pace, Morgan Dehnel, kindly put in a good word for me and my application was accepted at BSL without even going through an interview.

I was open to any role, as long as it had something to do with engineering or manufacturing. I began as a mechanical designer in the engineering team for a few months, then got transferred to the Quality Control department, where I worked for 4 years. The metrology course that I did at BCIT gave me an excellent head start for this QC inspector role and I learnt more than I thought I would in terms of general engineering knowledge and the actual products made at BSL.

After those years in Quality Control, I needed a change. I had noticed over the years that the Coil Shop (department where the electromagnet’s coils are manufactured) could use someone to improve some of the processes. With the product knowledge and various skills I had acquired at that point, I asked the general manager if he would be interested in creating that role for me and to my surprise, that’s what happened.

My current role is called “Tooling and Process Improvement Coordinator” and it involves dealing with anything that concerns quality of product in the coil shop and tooling design. The most exciting and rewarding part of my job is when I get an opportunity to model, manufacture improved tooling designs (either by 3D printing or machining) and test it out.

3D printing has been hugely helpful in my role because it allows for cheap and rapid prototyping various tooling. The plastic that’s 3D printed is often strong enough to be a functional part.

The picture shows an example of a simple Go-NoGo Gauge that’s used for measuring the thickness of a coil all around its profile. If sections of the coil don’t fit, that probelm has to be addressed, otherwise there will be fitment issues.

Process inspections are extremely important to avoid costly reworks or scrapping items, which is even worse.

I have been in New Zealand for 7 years already and still loving it, despite missing Canada and the many friends I have made there. The beautiful sceneries in this country are as great as the ones in British Columbia and the people are very friendly in general, so the transition has been smooth.

In my free time, I still enjoy skateboarding when I can and making sure that my ollies won’t deteriorate for as long as I can walk.